Looming machine damage may be noticed in the form of changed vibrations. If left undetected, the intensity of these vibrations continues to increase, which inevitably leads to system failure. The early detection of pending mechanical and electrical faults can prevent unplanned machine downtime.

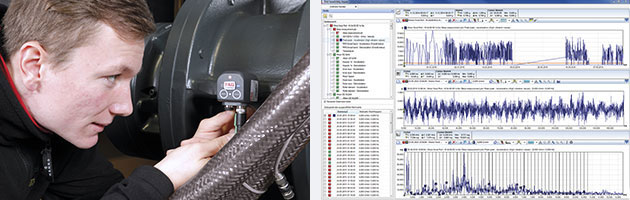

Baumüller Services uses the term "Condition Monitoring" to unite a sophisticated system of analyses and measurements in order to investigate the status of machines during ongoing operation and to thus detect anomalies at an early stage.

Constant monitoring of critical process parameters

Solutions as individual as your system

Condition monitoring is an essential component of modern maintenance planning. We work together with you to develop the ideal concept for your system and its components. Vibration analysis enables us to detect machine faults, such as imbalance or alignment errors, and damage to the bearings. The individual fault patterns can be defined by a selective frequency analysis. Mobile vibration sensors can also be used to identify possible fault sources at any location in the system.

Our goal is your benefit: The prevention of unplanned production downtimes

Your benefit

- Early detection to reduce downtimes caused by component wear

- Costs for consequential damages are prevented or reduced

- The continuous recording of measurements allows you to know the condition of your machines at all times

- Complete support, consisting of installation, commissioning, monitoring and repair, if required, is provided from a single source

- Optimum utilization of the wear margin

- Inspection cycles can be extended and maintenance work better planned