Early Detection of Hidden Sources of Faults

Almost every physical component overheats before it fails. Thermal imaging brings these hidden red flags to light. By performing a thermal analysis on your machinery and plant it is possible for us to detect the start of damage at an early stage and initiate corrective actions. This increases the reliability and safety of your plant.

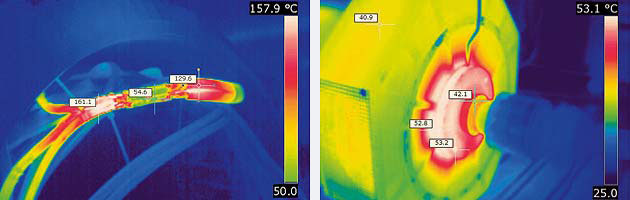

Thermal imaging is a non-contact diagnostics technique which makes it possible to inspect your machinery and plant even when in operation. Even difficult to access objects can be measured thermographically enabling mechanical and electrical hot spots to be detected before they cause a failure.

The evaluation of discovered hot-spots is an important element of the thermal analysis. The results are evaluated by our specialists and documented in a detailed report. Regular thermographic inspections produce a trend analysis that can detect gradually increasing variations and thus making it possible for you to take action.

Preventative Maintenance of Your Machinery and Plant with Thermal Imaging

Diverse Fields of Application

Common inspections for electrical items include power transformers, electronic cabinets, and defective insulators through to the simplest wire connection.

Overheating in mechanical components such as bearings, couplings, belts and gearboxes can also be detected and rectified in a timely manner by our service specialist.

Thermographic analysis is an important part of our Preventative Maintenance Program enabling you to increase the uptime of your machinery and plant.

Our Objective is Your Benefit: The Prevention of Expensive System Failures Through the Early Detection of “Invisible” Hotspots

Your Benefits

- Timely detection of pending electrical or mechanical failures

- Thermal analyses can be performed during machine operation

- Immediate notification of component hot-spots

- Documentation and evaluation of the measured data in an informative report

- Regular measurement produces a trend for the evaluation of the state of the plant or machine

- Quality verification for new electrical installations

- Risk minimization of fire hazards

Contact Thermal Imaging: service@baumuller.com