Your partner for mechanical and electrical repair

Everything depends on the transformer! It is responsible for ensuring the smooth functioning of the power supply. A failure or standstill costs a great deal of money. To increase the reliability of transformers, we recommend regular maintenance intervals. This protects you from unpleasant surprises and increases your production reliability. In addition, DGUV requires the regular maintenance and testing of transformer stations or transformers. As a specialist for industrial maintenance, Baumüller Services is happy to assist you with this and offers you fast, competent, and uncomplicated support in the mechanical and electrical maintenance of your transformers.

Cutting-edge diagnostics and testing systems

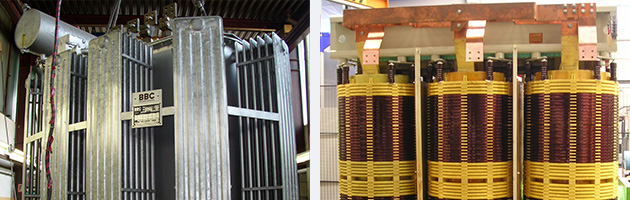

We have the expertise and the technical infrastructure to guarantee you systematic diagnostics along with good-as-new reconditioning. Our work is based on the applicable DIN, VDI, and VDE regulations. We are happy to support you in the maintenance of your transformers, regardless of whether these are oil transformers, dry-type transformers, or cast-resin transformers.

- Insulating oil testing according to DIN EN 60422

- High-voltage testing (winding test)

- Insulation measurement (such as polarization index)

- Partial discharge diagnostics and dissipation factor measurement

Extended life cycle through sustainable repair

Our services include comprehensive mechanical and electrical incoming inspection, the rewinding of coils, and the repair of coil cores. Thermographic analysis can be applied to detect further hidden damage. An independent special laboratory performs oil analyses, after which the oil is either processed accordingly or disposed of properly.

Excerpt from our service catalog:

- On-site inventory control

- Incoming inspection

- Troubleshooting

- Leakage repair

- Seal replacement

- Oil drying

- Cleaning (corrosion and rust removal)

- Welding and painting work

- Repair of coil cores

- Rewinding of coil cores

- Outer cone elongation

What you can rely on:

- Simplified order processing thanks to provision of all services by one high-performance partner – from derigging and overhaul to recommissioning – service from a single source

- Regular maintenance of your transformers extends the overhaul intervals and increases the availability of your machine

- All tests and work steps are carried out and documented in accordance with the applicable standards

- Comprehensive services – also on site

- Upon request, we can take care of the full-service processing from derigging, transport logistics and repair to upgrading and recommissioning.