Manufacturer-independent and sustainable repairs

Baumüller Services is your competent partner when it comes to the manufacturer-independent repair of your direct current and three-phase motors. Thanks to our many years of experience in drive technology, we can offer you flat-rate prices for defined service packages. This enables us to provide faster and more efficient processing – from the initial inquiry all the way to the delivery and re-commissioning of your electric motor.

Baumüller Services: Your partner for all service needs

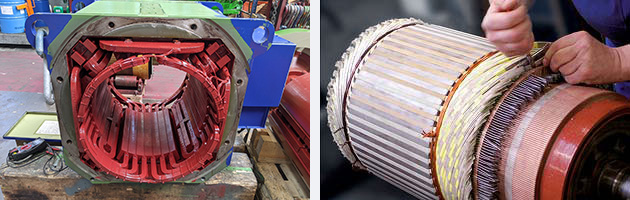

Our services for AC/DC electric motors range from mechanical overhaul to the rewinding of the stator and rotor. We not only replace defective parts, but also check and replace all wear parts wherever necessary.

Digitally assisted diagnostics and processes

Many of our processes are computer-controlled, which allows us to achieve high-quality results. From environmentally friendly, sustainable, and quality-conscious thermal de-insulation in a pyrolysis furnace, to the air bubble-free infusion of all winding parts in our vacuum pressure impregnation system.

From the replacement of defective components to full maintenance

Baumüller Services guarantees quality and delivery reliability by providing all services in-house. Our testing facilities meet the latest technical and environmental requirements. This way, we ensure reliable diagnostics and the highest quality standards for your electric motors.

Express repairs – We are your partner in need!

We know how critical situations can become when production units fail. Thanks to our 24-hour service, we are ready to help you and your electric motor 7 days a week.

Preventive maintenance means safety!

It is important to ensure safety and to be able to rely on electric motors and machines. We are also happy to offer assistance after an emergency. The preventive maintenance of your DC and AC electric motors in the scope of a service partnership agreement can help you enormously in minimizing any unexpected downtimes of your production machines.

What you can rely on

- An experienced service partner for the complete range of your electric motors – independently of the manufacturer

- Transparent costs due to fixed deadlines and fixed prices for defined service packages for the electric motor

- Accessibility 24 hours a day, 7 days a week and fast on-site troubleshooting for your electric motor when necessary

- Short standard delivery times with optional express repair and thus reduced downtimes

- High quality thanks to full in-house provision of services and the use of original spare parts for almost any electric motor

- 12 months warranty on repairs with option of warranty extension through regular maintenance

Our maintenance and services

- Condition assessment

- Cleaning of windings (also on site)

- Turning of collectors and slip rings (also on site)

- Renewal of brush holders and carbon brushes

- Balancing/field balancing on installed machines

- Rewinding of low-voltage electric motors of all types

- Rewinding of high-voltage electric motors in state-of-the-art VPI or conventional resin-rich technology

- Renewal of laminated cores

- Reconstruction of slip ring bodies

- Installation of thermal sensors in windings and for bearing monitoring

- Mounting of terminal boxes

- Incoming inspection i.e., electrical, and mechanical inspection

- Disassembly and diagnostics

- Repair of explosion-proof motors

- Damage analysis with preparation of a cost estimate

- Cleaning of the parts, and if necessary, washing and drying in the furnace

- Replacement of defective parts and mechanical repair

- If necessary, manufacturing of the winding with intermediate test according to VDE

- If necessary, dynamic balancing and vibration measurements

- Assembly

- Testing according to VDE in our test bay, with test report upon request

- Preservation

- Replacement of shaft seals (WA, WAS, WA Viton, WAS Viton), replacement of ball bearings (deep groove ball bearings, NU bearings, current-insulated bearings and others as needed)

- Bushing of bearing shields, turning to size

- Renewing of motor windings of all types and professional disposal of old windings

- Test run on the machine test bay, electrical and mechanical assessment