![]()

Retro derives from Latin and means something like "backwards". I.e. a trend from an earlier period suddenly becomes very fashionable again. The English word "fit" is perhaps best translated into German as "passend". A retrofit, therefore, is when an old machine that is past its prime is reconfigured for current technical conditions. Here you will find out exactly how this works.

What is retrofit?

"A retrofit includes various measures aimed at increasing the efficiency and performance of the machine."

Norbert Süß, Head of Service, Retrofit at Baumüller

A retrofit includes various measures aimed at increasing the efficiency and performance of the machine. Both individual components and complete drive systems can be upgraded. Often a machine controller will be upgraded and a modern operating unit (HMI) will be installed. Modern digitization tools can of course also be added for remote service or a diagnostic tool. All of these lend new shine to the old machine and enhance its performance enormously.

Reasons for retrofit

The replacement of obsolete components to meet the standards of state-of-the-art technology increases the productivity and energy efficiency of machines. With a retrofit, you as a system operator can benefit from significantly lower costs compared to the acquisition of new production systems. Here, the basic substance of your machine, usually very stable and high-quality, is preserved and in case of large machines there is no major expenditure incurred for replacements, such as for building a machine base, for example. The production downtime is thus greatly reduced thanks to a retrofit.

Advantages of a retrofit:

Modernize while saving energy

Saving energy can be that simple: With a well designed retrofit, it's possible.

Increase machine availability

High output needed: Fewer machine failures increase availability significantly.

Long-term increase in efficiency

We realize your individual requirements: This results in an increase in the efficiency of the machine that will last.

Improve replacement part availability

There for you in the future as well: Guaranteed replacement parts supply for your modernized machine.

Our services:

Consultation

![]() What drives you?

What drives you?

Do you want to increase your machine availability and modernize your system? We support you right from the start. Your individual requirements for the retrofit are our primary concern.

First steps:

- Identification of customer requirements

- Determination of the scope of the retrofit

- Agreement on the overall scope and framework conditions

Concept

![]() Conception phase

Conception phase

What products are perfect for your system? How can your machine fully realize its potential? Which retrofit concept makes the most sense for you?

Our services:

- Technical analysis of the entire system, consisting of:

- Review of existing control or automation systems (manufacturer-specific)

- Creation of appropriate retrofit concepts

- Preparation of a quote

Planning

![]() Comprehensive scheduling

Comprehensive scheduling

What is important to you? When should the retrofit be completed and how exactly should commissioning be carried out? All of this is laid out in the requirements specifications and functional specifications.

Our services:

- Preparation of requirements specifications and functional specifications with customer

- Planning of retrofit and commissioning of the machine in coordination with customers

Implementation

![]() Engineering the system

Engineering the system

We program your machine solution and take care of the procurement of all necessary components.

Our services:

- Software development and testing

- Project planning of circuit diagrams and drawings

- Component ordering and if necessary control cabinet construction

- Pre-commissioning and simulation

- Retrofit of the machine

Commissioning

![]() Step-by-step commissioning

Step-by-step commissioning

We commission your system and test all components.

Our services:

Commissioning consisting of:

- Installation testing

- Hardware and software tests

- Parameterization and optimization of the entire machine

- Production assistance

Acceptance testing

![]() Handover of the completed project

Handover of the completed project

The retrofit was successfully completed. You can now proceed with acceptance testing.

Our services:

- Handover of project documentation

- Acceptance of implemented project with the customer

- Preparation of acceptance log

Service

![]() At your side 365 days a year

At your side 365 days a year

Preparation of a long-term maintenance and service concept – to maintain your productivity.

Our services:

- Fast replacement part supply

- 24/7 hotline

- Remote service

- Continuous service (inspection, maintenance)

Manufacturer-specific solutions for modernization

Regardless of manufacturer, we offer you tailored and multi-level solutions for modernization of your electrical drive systems. With new drive components and control solutions you will quickly achieve greater flexibility and increase the productivity of your system – and while keeping investments at a manageable level. We equip existing machines with the most modern drive systems, control technology and user interfaces, thus allowing high system availability and process reliability.

Retrofit examples with different machine types

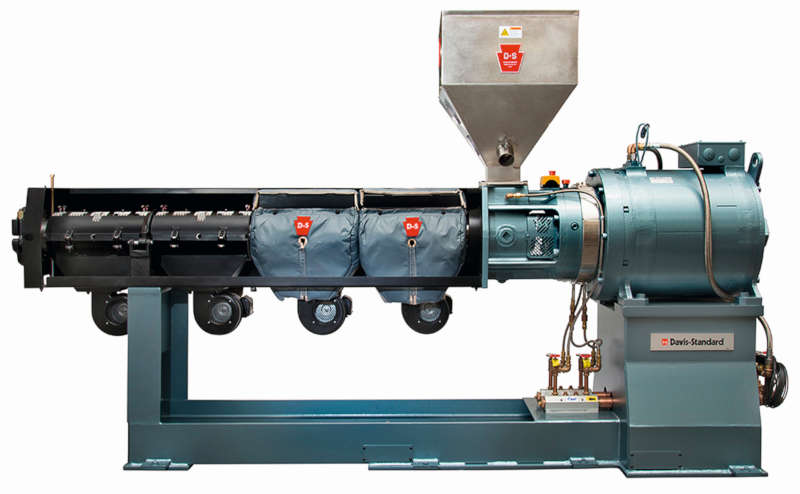

1. Extrusion machines

Common reasons for retrofitting extrusion systems include energy savings (in some cases up to 50 percent is possible) and replacement part availability. Because of in some cases very high energy savings, the investment in a retrofit often pays for itself in two years.

Common reasons for retrofitting extrusion systems include energy savings (in some cases up to 50 percent is possible) and replacement part availability. Because of in some cases very high energy savings, the investment in a retrofit often pays for itself in two years.

Your benefits at a glance:

- Significant savings in energy consumption

- Reduced space requirements of your machine

- Low-maintenance drive elements for increased availability of your machines

- Increased overall efficiency of the drive system

- PLC in the drive and external temperature regulation

- Replacement part availability

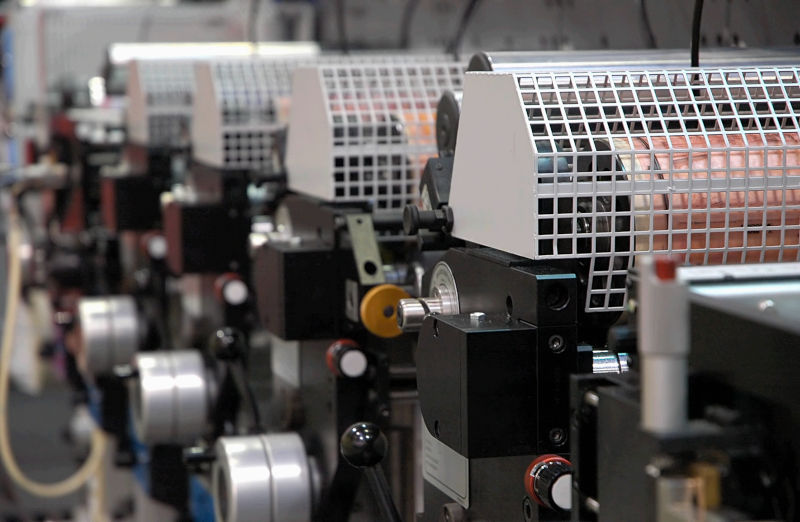

2. Printing machines

Common reasons for the retrofit of printing machines are replacement part availability and machine availability. As printing machines have a very robust design, there is no need to replace the machine. In these cases a retrofit or a partial retrofit is entirely sufficient to achieve the productivity of a current machine.

Common reasons for the retrofit of printing machines are replacement part availability and machine availability. As printing machines have a very robust design, there is no need to replace the machine. In these cases a retrofit or a partial retrofit is entirely sufficient to achieve the productivity of a current machine.

Your benefits at a glance:

- Time and cost savings through modernization instead of acquiring a new machine

- Future security through guaranteed replacement part and service availability

- Increased reliability through modernized technology

Retrofits of electrical motors and converters

With new drive components you will quickly achieve greater flexibility and increase the replacement part availability of your system – and while keeping investments at a manageable level. Retrofitting existing machines to state-of-the-art drive systems allows high machine availability and process reliability.

Optimized solutions according to plan

After an inventory and analysis of currently installed drive technology, we will create a detailed quote for your company covering your optimized drive systems for the retrofit.

Based on your requirements, we will plan and define parameters for a drive system outfitted with the latest technology. In addition, we offer, along with the drive modernization, detailed training of your personnel in the new system so that you can enjoy the benefits of the drive modernization.

» GOAL: Increased efficiency of your machines and systems

Your benefits

- We handle the entire project execution for drive modernization – service from a single source

- Longer service life for your machine with the installation of modern technology and long-term component availability

- Increased availability of your machine through reduced likelihood of failure due to wear and tear

- Reduction of operating costs through the use of modern and reliable drive components for automation

- Increase in energy efficiency of your production through modern and low-consumption drive systems

- High replacement part availability

- High product quality

Non-binding advice - Get in touch with our experts!

Norbert Süß

Head of Service, Retrofit

n.suess@baumueller-services.com

+49 911 9552-969