Almost every technical component heats up before it fails. A thermal imaging analysis of your machines and systems enables us to detect and clear pending faults at an early stage. This increases the safety and reliability of your system.

Thermal imaging is a contact-less diagnostic procedure that permits inspection of your machines and systems while in operation. Even objects that are difficult to access can be recorded with thermal imaging. Mechanical and electrical weak points are thus detected before they cause failure.

The evaluation of detected hot spots is an important component of thermal imaging analyses. The results are evaluated by our technical personnel and documented in a detailed report. Routine thermal imaging inspections produce a trend analysis that can determine creeping deviations and thus enable timely action.

Preventive maintenance of your machines and systems using thermal imaging analyses

Diverse fields of application

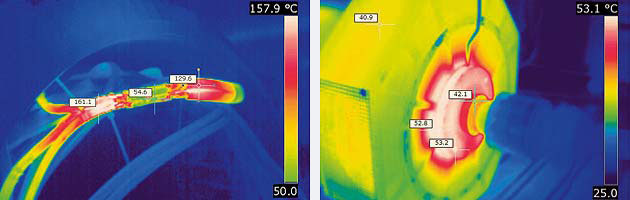

Thermal imaging analyses can be used in many ways. They are well suited, for example, for checking electrical equipment, such as switch cabinet systems, and thus for detecting unbalances and overloads. Damaged insulators and crimped connections can also be identified.

A thermal imaging analysis can also be used to detect and remedy overheating in mechanical components, such as bearings, sheet metal packages and gears, at an early stage. This makes thermal imaging analyses an important instrument for the preventive maintenance of your machines and systems.

Our goal is your benefit: Prevention of expensive system downtimes with early detection and clearing of pending faults

Your benefit

- Increase in workplace safety thanks to early detection of possible hazards

- Thermal analyses are performed on running machines – without impairing their operation

- Early detection to reduce downtimes caused by component wear

- Routine measurements produce a trend for evaluating the system or machine status

- Documentation and evaluation of the measurements in meaningful reports

- Quality certificate for new electrical installations